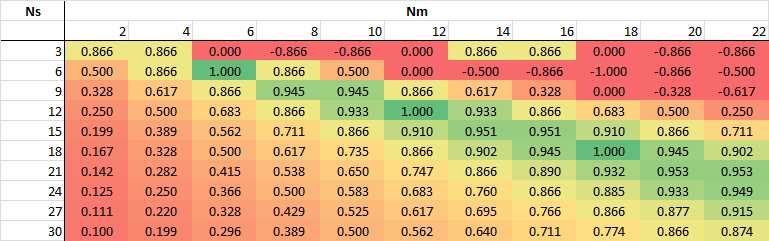

Induction Motor Slot Pole Combinations

36 pole induction motor

Induction Motor Slot Pole Combinations Chart

36 pole induction motor

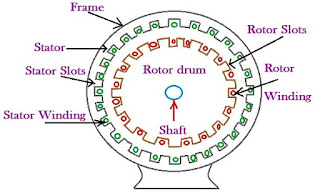

During grid motor starting from zero rpm, this starting current flow is in the upper part of the bar close to the rotor OD. (due to the skin effect of current penetration). AS the motor increases speed the bar current is distributed down in the lower part of the bar & the frequency seen by the bar decreases (decreasing slip). The comparison of electromechanical characteristics of a 4-pole and a 6-pole induction motor with 36 stator slots in combination with 28, 33, 34, 44 and 46 rotor slots is presented. Rewinding 3 Phase Motor: Hello everyone, i am Niko and, in this instructables i will show you, how to rewind and renew old three phase electric motor.If you are searching for rewinding of one phase motor you can find it here.In this insctructables, i am going to make step f. I-B depicks a (3) phase (4) pole, (6) slot brushless motor with the coils wound around a single stator tooth the same as Figure I-A. Figure I-C is an (8) pole, (18) slot motor with (3) phases and a (2) slot coil winding pitch. Figure I-D is a common brushless configuration for (3) phase motors with (4) poles.

Induction Motor Slot Pole Combinations Generator

I'm in the process of trying to design a 36 pole induction motor for one of our test beds in the factory. It'll be used to test a range of winches that we manufacture and by controlling this motor through a VSD we can perform certain tests without the primary gear box that gets fitted to the completed unit.

I've looked on the web at the various motor manufacturers - a motor of this size (55kW)does not exist as far as I can see, hence my efforts to design a fit for purpose motor.

Despite my best efforts, all I can achieve is a 25kW design, that runs, but with a terrible power factor (copper losses and a huge differential reaction are killing the machine).

My question (eventually) is this: is this a viable proposition in motor design? Should I be looking at a different type of motor (such as a brushless DC or similar)?

Has anybody had any experience with a motor of this size?

Best Regards